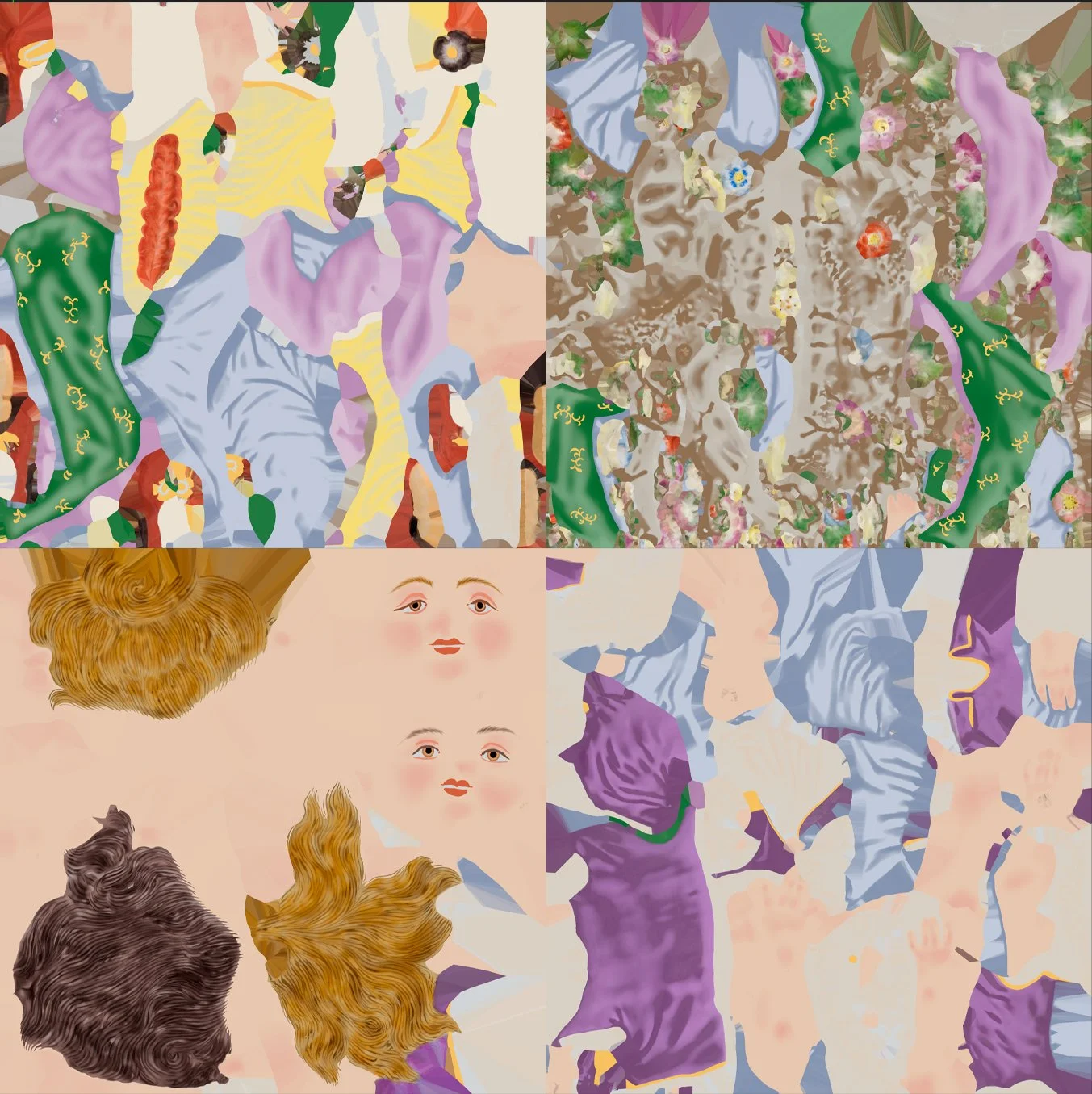

Porcelain Series

Color Systems & Digital-to-Physical Fabrication

National Gallery of Victoria, Melbourne

Project Overview

A series of monumental mirror-polished stainless-steel sculptures finished using layered transparent automotive paint systems.

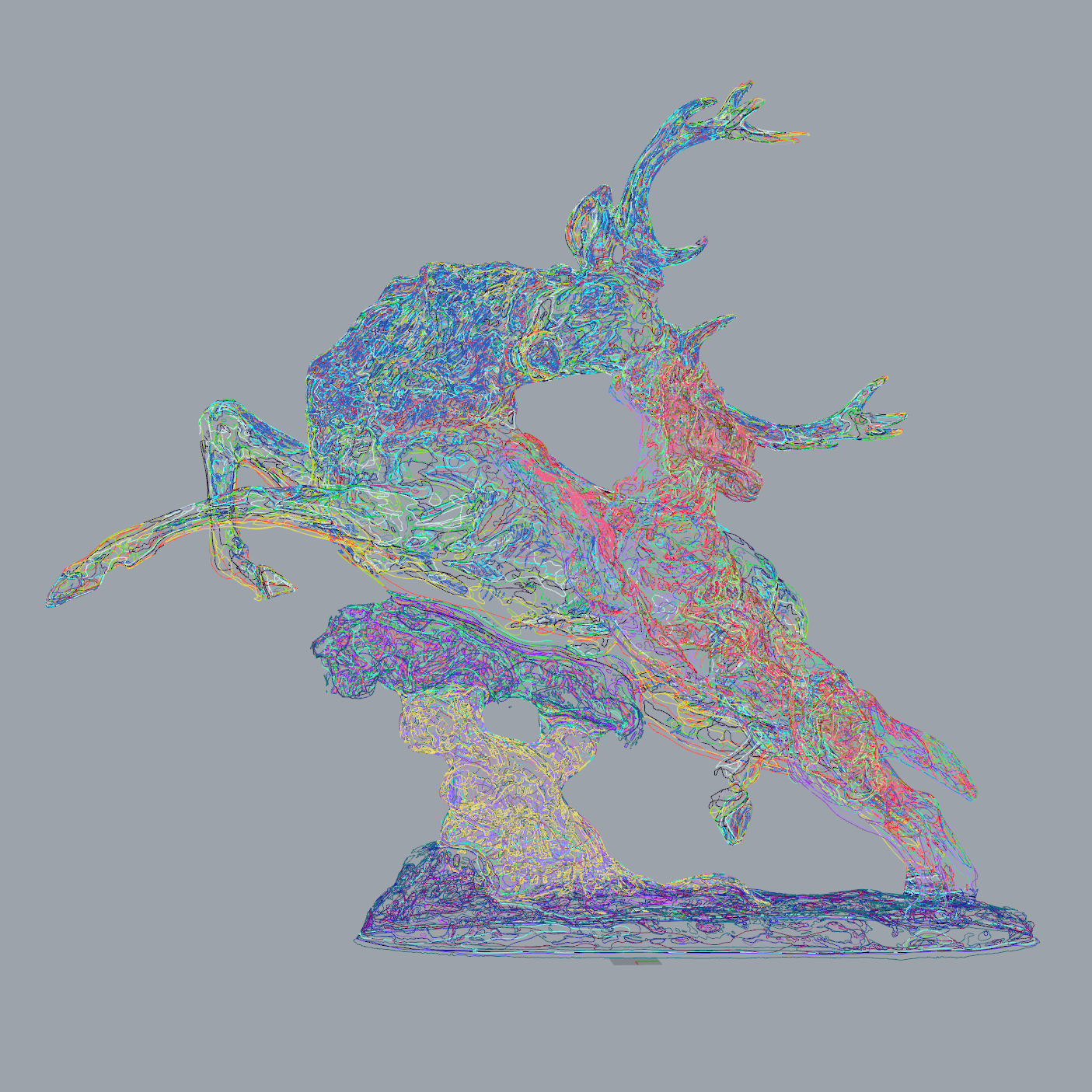

I served as Project Lead for color development, designing and managing the complete digital-to-physical workflow to ensure accurate translation from the artist’s original model to final fabrication.

Role

Color system design and execution

Digital repainting and rendering

Masking strategy and fabrication translation

Team leadership and on-site production oversight